Semi Automatic Fillers-4

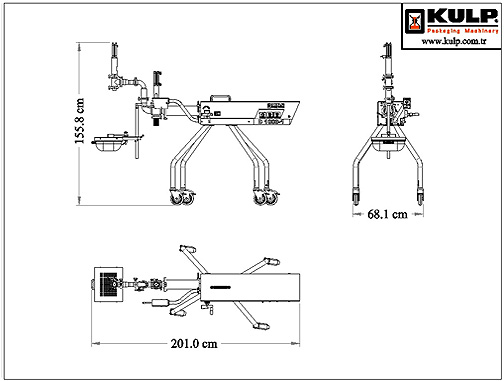

Model No.: D1001+SN042 | Made in Turkey, Kulp Packaging Machinery

Download Product Brochure

These Semi Automatic Fillers are Offered with Various Filling Ranges and Capacities in terms of packages per hour

These fillers are used for Filling Items like Honey, Tahina, Molasses, Oils, Syrup, Fruit Juice, Fruit Concentrates, Vinegar, Ketchup, Milk, etc.

| Model

No |

Filling Range

(ml) |

Filling Range of Optional Cylinder |

Capacity (Packages /Hour) |

Air Consumption Litres/Min |

| D 50 |

5-50 |

2-20 |

1800 |

100 |

| D150 |

15-150 |

5-50 |

1500 |

100 |

| D 500 |

50-500 |

20-200 |

1000 |

300 |

| D 1000 |

100-1000 |

20-400 |

720 |

300 |

| D 2000 |

200-2000 |

50--1000 |

600 |

300 |

| D 5000 |

500-5000 |

145-1450 |

420 |

300 |

Technical Details :

- This is a volumetric filling machine that works with FESTO pneumatic system.

- It primes the product from its SS 316 L seamless stainless steel hopper.

- The seals are manufactured from teflon ,viton or polyethylene according to the product to be filled.

- The parts on the machine are connected by tri –clamps.

- The machine stands on a stainless steel frame which is supprted by 4 castors, it can be easily move to anywhere.Materials Used on the fillers :

- The parts that contact with the product are 316 L stainless steel. The other parts are 304 L stainless steel and anodized aluminum.

- FESTO Pneumatic Equipment. (Oil-free)

OPERATING TEMPERATURE :

From +5 ºC to +85 ºC with standard sealings.

Above 90 ºC with special sealing.

FILLING ACCURACY : ± %1

Note: Technical specifications are subject to change without prior notice due to ongoing research & developments.

Features

- Easy to adjust and record the filling range by the numerator and the hand wheels.

- High surface smoothness and argon arc welding technology prevents contamination.

- The nozzle, main valve and the filling piston are designed for an easy-cleaning. They can be dismantled easily without using any tool.

- Interchangeable nozzles are available according the product, either it is liquid, viscous or particulated.

- There is a height adjustable platform on the filler to place the packages during the filling process.

- The detailed instruction manual for each model is available.

Accessories :

Back

Side

Cleaning System |

It is designed to

clean the back side of the sealing system for sticky products. |

SN02

Filling

Nozzle |

This filling nozzle is

used to fill liquid and viscous products starting from 100ml. |

Additional

Filling Cylinder |

This interchangeable

piston enables you to fill from 20ml to 400ml |

| Foot

Pedal |

For Operating the

Filler By Foot

|